-

HomeHome

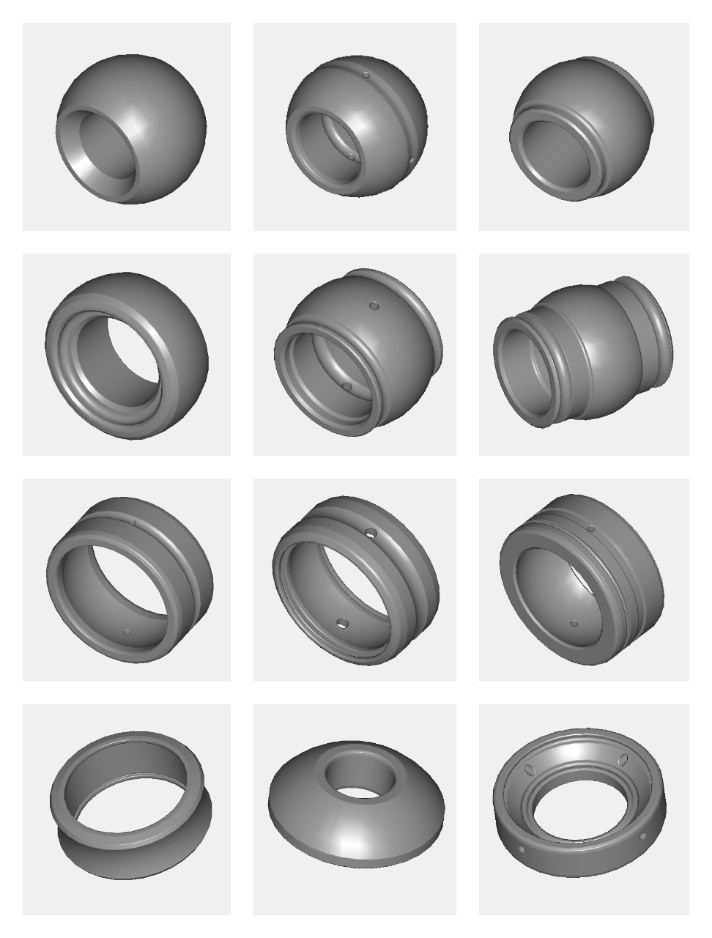

Accurate Rotating Parts and Spherical Plain Bearing components

We produce accurate rotating parts according to customers request. We manufacture finished products or we do only required technology processes (hardening, grinding, super finishing, washing, etc.) on parts delivered by customer.

Custom rings

VRL Praha a.s offers you the production of rotary parts, the functional surfaces of which are ground (spacer rings, bearing bushes, precision washers or other parts with a tolerance of hundredths or thousandths of a millimeter), which, due to their similarity to bearing rings, allow us to take advantage of our machine park.

The customer-specified rings are turned, heat-treated, ground (face grinding, cylindrical grinding of the outer and inner surfaces), or super-fine grinding and honing of the outer spherical surfaces).

Our machine park allows us to offer the finished parts with an outer diameter of up to 60 mm.

We can offer turned parts up to an outside diameter of 65 mm like series production.

Spherical plain bearing components - inner and outer rings

Spherical plain bearings: grinded OUTER RINGS up to 62 mm OD, grinded INNER RINGS with their outer spherical surface (raceway)up to 53 mm and their bore size up to 40 mm

Spherical bearings belong into the group of plain bearings. They consist from outer and inner ring with a spherical sliding face. They are used for high surface pressures. With respect to the non-efficient lubrication, the spherical bearings are used only for slow pendulous motion. Their design enables only minimal needed maintenance and they usually show almost no wear. The rings are made from hardened bearing steel (14 109.4, 100Cr6). Gliding surfaces are ground and super finished. Allowed working temperature of steel plain bearings range from –200°C till +400°C.

VRL Praha produces plain joint bearings in basic design, with normal radial clearance and in dimensions mentioned in the following catalogue. Spherical plain bearings with other design, form or variation can be manufactered according to customer’s requests and needs.

We produce the components (inner rings and outer rings) for spherical plain bearings and rod ends of the standard series (GE, GEH, GEM, GEK) and also for special production in smaller series.

Our grinding machines allow us to grind outer rings with outer diameter up to 62 mm and inner rings with outer diameter up to 53 mm.

We offer our customers OEM production of spherical plain bearings in the basic design, with the usual radial internal clearance and in the dimensions specified in our catalogue.

At the customer’s request, we can also produce other versions that differ in terms of shape and dimensions.

Dimension in [mm]

Designation | d | D | B | C | d 1 | d 2 | a [°] | weight [g] |

|---|---|---|---|---|---|---|---|---|

| GE 4 | 4 | 12 | 5 | 3 | 6 | 8 | 16 | 2,7 |

| GE 5 | 5 | 14 | 6 | 4 | 8 | 10 | 13 | 4,7 |

| GE 6 | 6 | 14 | 6 | 4 | 8 | 10 | 13 | 4,3 |

| GE 8 | 8 | 16 | 8 | 5 | 10 | 13 | 15 | 6,9 |

| GE 10 * | 10 | 19 | 9 | 6 | 13 | 16 | 12 | 11,3 |

| GE 12 * | 12 | 22 | 10 | 7 | 15 | 18 | 11 | 16,4 |

| GE 15 * | 15 | 26 | 12 | 9 | 18 | 22 | 8 | 27,4 |

| GE 17 * | 17 | 30 | 14 | 10 | 20 | 25 | 10 | 41,6 |

| GE 20 * | 20 | 35 | 16 | 12 | 24 | 29 | 9 | 66,2 |

Basic geometric tolerance

| d [mm] | tolerance [mm] |

|---|---|

0 – 10 | 0 / -0,008 |

10 – 18 | 0 / -0,008 |

18 – 30 | 0 / -0,010 |

| B [mm] | tolerance [mm] |

0 – 30 | 0 / -0,120 |

| D [mm] | tolerance [mm] |

|---|---|

0 – 18 | 0 / -0,008 |

18 – 30 | 0 / -0,009 |

30 – 50 | 0 / -0,011 |

| C [mm] | tolerance [mm] |

0 – 30 | 0 / -0,240 |

Other variants and designs

Except for the basic range of radial spherical bearings (GE variants) in complete units, VRL Praha a.s. can also offer the separate rings of different shapes, forms and designs. These rings can be delivered in lathe-turned versions as well as with ground bore, ground raceway and faces according to customer’s request. Other production operations, such as drilling of lubrication holes or lathe-turning of outer and inner oil grooves, need to be agreed for every single case. The pictures below are only illustrative.